Elevating Print Projects: Essential Post-Printing Processes and Finishing Techniques #

When your posters, cartons, catalogs, notebooks, and other printed materials come off the press, the journey is far from over. The post-printing (post-press) process is a crucial stage that transforms printed sheets into polished, professional products ready for use or distribution. Understanding these finishing techniques is key to achieving the highest standards for business, creative, or personal projects.

Why Post-Printing Matters #

Many underestimate the complexity and importance of post-printing. Whether your project uses offset, letterpress, or digital printing, several essential steps must be completed to ensure a refined final product. Post-printing encompasses a wide range of services, each contributing to the quality, durability, and visual appeal of your materials.

Key Post-Printing Processes #

- Folding: Ensures materials are neatly and accurately folded, essential for brochures, booklets, and more.

- Cutting: Precision cutting is vital for clean edges and custom shapes, enhancing the professional look of your project.

- Tidying (Finishing): Organizes and aligns pages or components, guaranteeing readability and a polished appearance.

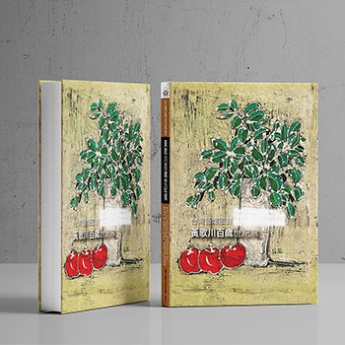

- Sewing & Binding: From sewn paperbacks to saddle stitching, perfect binding, spiral, and ring binding, proper binding keeps content in order and improves usability. Binding methods have evolved over 2,000 years, but the goal remains the same: a durable, readable product.

- Inserting: Adds supplementary materials or inserts, providing additional value or information.

- UV Coating: Protects against fading and damage from sunlight, preserving color vibrancy and material integrity.

- Bronzing (Hot Stamping): Uses heat and pressure to apply metallic or pigmented foils, creating eye-catching accents and a premium feel. Options include holographic, non-metallic, and pigment foils.

- Embossing: Creates raised (embossed) or recessed (debossed) designs using convex and concave dies. Embossing adds tactile and visual interest to cards, books, brochures, and more. The effect can be further enhanced with gilding or color.

- Die Cutting: Enables the creation of custom shapes and intricate designs, expanding creative possibilities.

- Matte Lamination: Adds a protective, non-glossy finish that enhances durability and resists smudges, stains, and moisture. Lamination is ideal for menus, business cards, posters, educational materials, and more.

- Silk Screen Printing: Allows for bold, vibrant designs on fabric and other surfaces, suitable for custom T-shirts, promotional items, and unique print effects.

- Thermal Gloss: Applies a glossy finish to selected areas, making colors more vivid and providing additional protection.

Benefits of Professional Post-Printing #

- Expertise & Equipment: Professionals have access to specialized machinery and techniques, ensuring consistent, high-quality results.

- Cost Efficiency: Outsourcing post-printing eliminates the need for costly equipment investments and reduces the risk of errors.

- Quality Assurance: Professional finishing guarantees that materials are properly aligned, bound, and protected, enhancing both appearance and longevity.

- Convenience: Delegating post-printing tasks saves time and reduces stress, especially for large or complex projects.

Common Applications for Post-Printing Finishes #

- Books and Catalogs: Binding, embossing, and lamination for durability and presentation.

- Business Materials: Foil stamping, UV coating, and die cutting for a premium look.

- Menus and Educational Materials: Lamination and UV protection for longevity.

- Promotional Items: Silk screen printing and custom die cuts for unique branding.

Featured Post-Printing Services #

By understanding and utilizing these post-printing processes, you can ensure your printed materials not only look exceptional but also stand the test of time.

Common Binding

Common Binding Glazing

Glazing Bronzing

Bronzing Rolling type

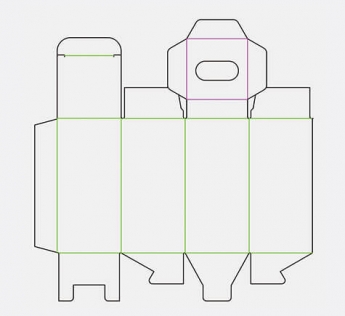

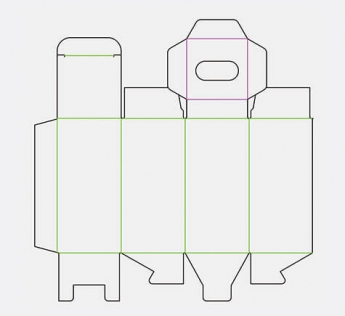

Rolling type Glue box

Glue box Convex / Concave

Convex / Concave Origami

Origami platform cutting

platform cutting